Alloy 5083 Aluminum Plate Sheet

Alloy 5083 aluminum plate sheet have higher strength than 5052 plate and has exceptional thermal conductivity. In the tempered condition, it retains good formability due to excellent ductility. It is highly suitable for welding and can be hardened by cold work. Because Alloy 5083 exhibits excellent resistance to general corrosion, it is used in marine applications. Since Alloy 5083 is capable of withstanding extremely low temperatures without brittleness or loss of properties, it is especially suited to the cryogenic market.

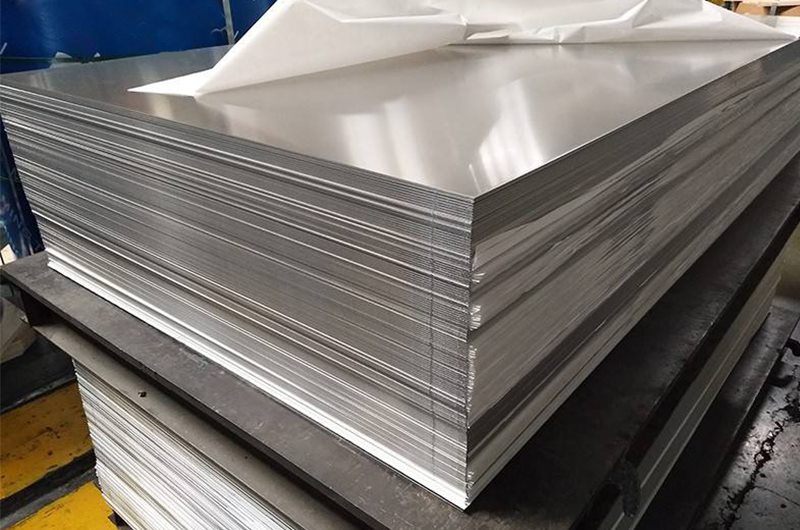

5083 aluminum plate with high strength

Typical application of 5083 alloy

Applications:LNG ship construction,Pressure vessels,Storage tanks,Welded structures (high strength),Armor plate,Drilling rigs,Plate for ship building, unfired welded pressure vessels, rail and other vehicles, various structural applications that make use of the high strength.

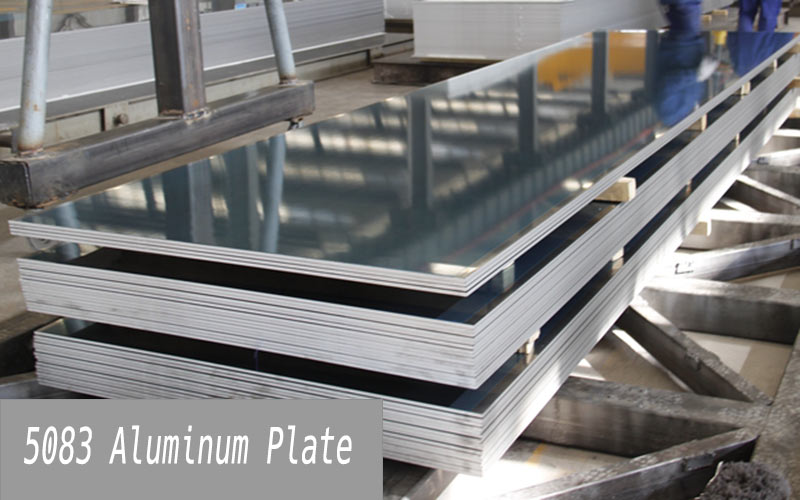

Temper: O, H111, H112, H116, H321,H12,H14, H16, H18, H32, H34, H36

Thickness: 0.2mm--200mm

With: 500mm--2800mm

Length: 1000mm--12000mm

Surface: Mill finish, Bright finish, paper interleaved, one side film, both sides film.

We can provide aluminum material samples free of charge, and there is no specification. (mold opening and customization, and the mold cost shall be borne by the customer)

Free sampling

5083 is the highest strength of any of these alloys. Alloy 5083 aluminum plate is the most well-known plate for shipbuilding. In addition, it is also used to manufacture aircraft fuel tank, oil pipe, aircraft plate welding parts, vehicle materials, sheet metal parts of automobile transportation and ships, instruments, street lamp supports and rivets, hardware products, electrical enclosures, pressure vessels that need to be strictly fireproof (such as liquid tank truck, refrigerated truck, refrigerated container), etc.

5083 aluminum plate is used in all aspects

5083-O aluminum sheet can be used for low-temperature storage tanks, because 5083 aluminum alloy has high strength at low temperatures, is light in weight, is corrosion-resistant and can ensure safety during ocean transportation.

Since liquefied natural gas needs to be transported by ships at a temperature of minus 162 degrees Celsius, liquefied natural gas storage tanks must be able to resist brittleness at low temperatures. The 5083-O aluminum plate just solves this problem.

5083 aluminum plate is used for low temperature storage tank

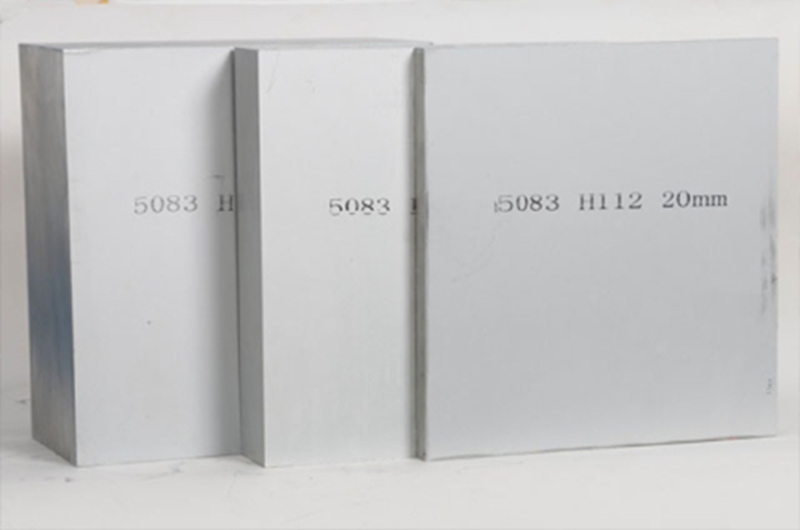

5083-h112 aluminum plate

5083 aluminum plate classification

|

product |

5083 aluminum plate |

|

Aluminum plate variety |

Ordinary aluminum plate, bright aluminum plate, wire drawing aluminum plate, film coated aluminum plate, super flat aluminum plate, imported aluminum plate and patterned aluminum plate |

|

standard |

GB、ASTM、EN |

|

Delivery status |

o、H111、H112、H116、H131、H32、H321等 |

|

thickness |

0.5-450mm |

O: The annealed condition is applicable to the processed products (occasionally) that have been fully annealed to obtain the lowest strength

H: Non heat treatment strengthened aluminum alloy

The first digit indicates the method of work hardening.

The second digit indicates the degree of hardening achieved by the material.

H followed by an Arabic numeral

H1 only indicates the work hardening state, which is applicable to the products that obtain the specified strength without heat treatment after work hardening;

H3 work hardening and stabilization state is applicable to products with stable mechanical properties after work hardening through low-temperature heat treatment or due to the thermal effect during hot working. Stabilization can usually improve ductility. This code is only applicable to alloys that gradually age soften at room temperature.

HX1 (x for 1, 2, 3) followed by an Arabic numeralYes! I'm interested

H1, H2 and H3 status codes are followed by an Arabic numeral to indicate the degree of work hardening.

Hxx code followed by Arabic numerals

When there is a difference but close to the control degree or mechanical properties (or both) of hxx state, or there is a significant impact on the determination of other characteristics, the third Arabic numeral shall be used.

For example, Hx11 is suitable for sufficient work hardening when the final annealing does not meet the requirements of annealing state,

However, the work hardening degree is not completely consistent with the HX1 state;

H112 is applicable to products with certain characteristics obtained during thermal processing, which have mechanical property requirements.

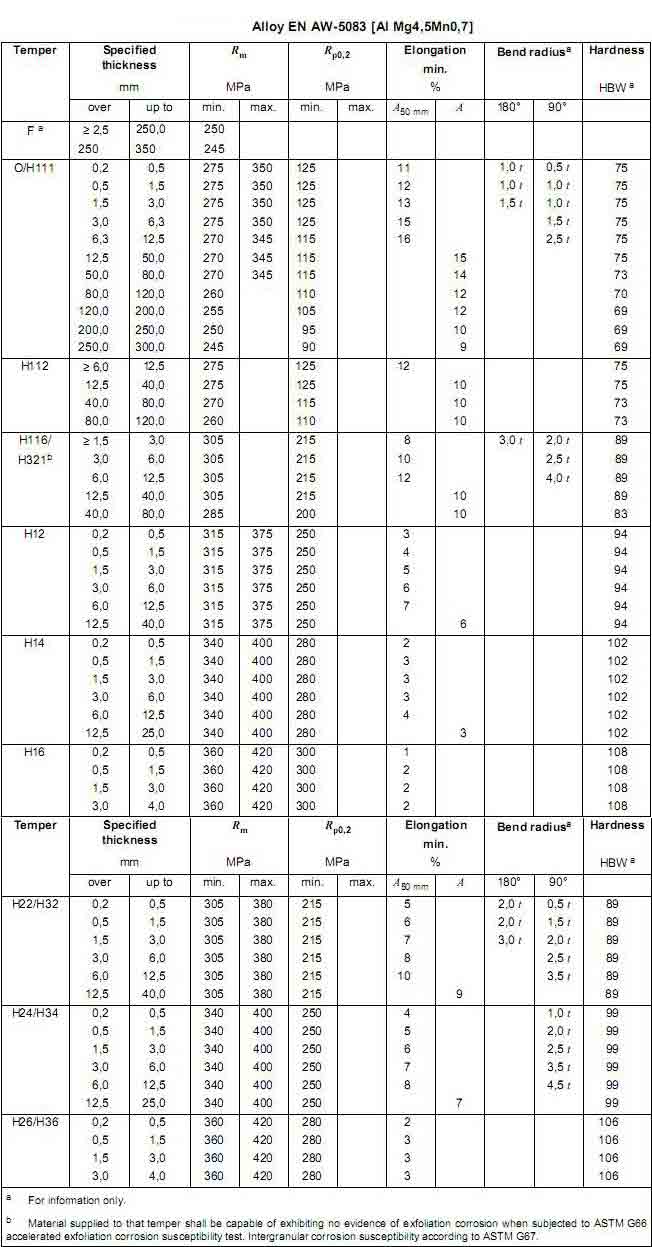

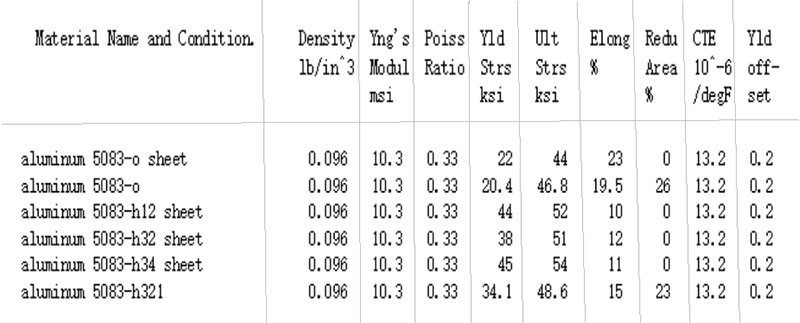

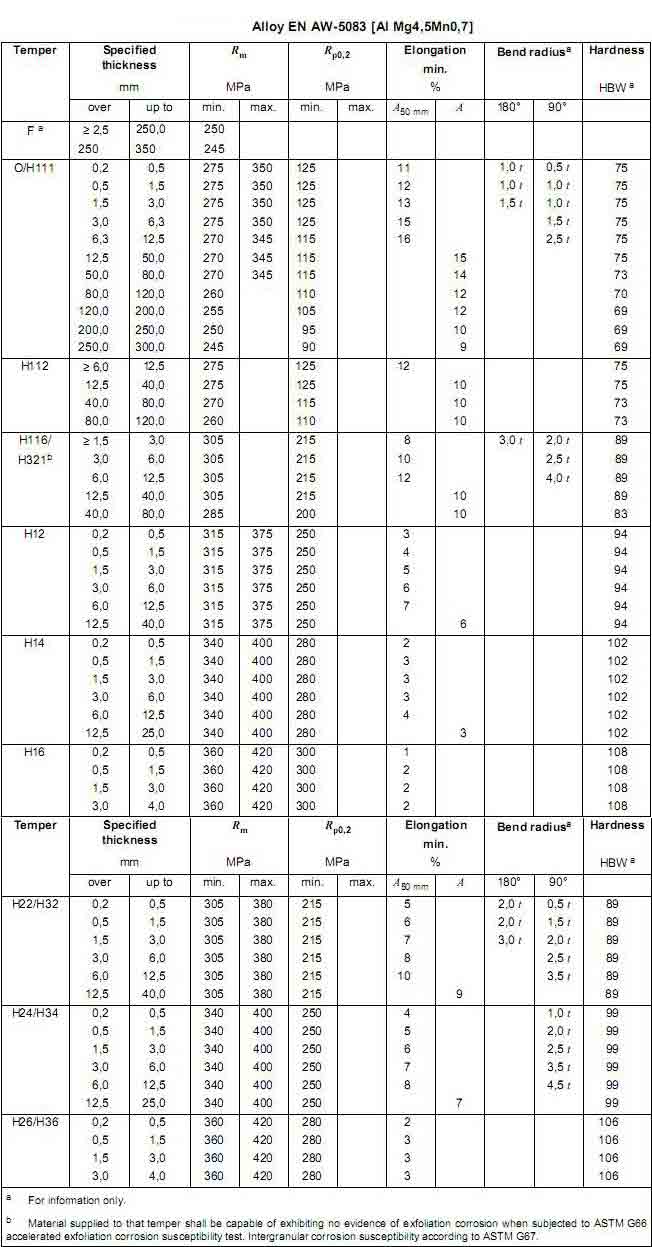

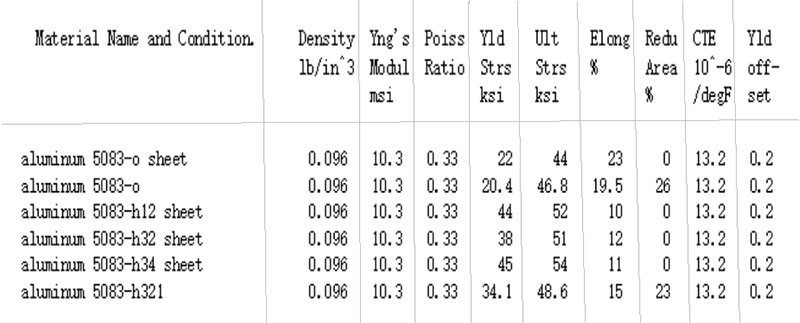

Physical properties of 5083 aluminum plate in various states

Other applications of 5083 alloy:

5083 aluminum alloy can not only be used as plate in shipping and transportation industries, but also as aluminum foil, aluminum strip and aluminum profile in all aspects of life.

For example:

-

1. 5083 pattern aluminum plate is used for anti-skid of refrigerated vehicles, cold storages, refrigerators and subways

-

2. 5083 aluminum coil is used for auto parts, high voltage switch, ship plate, tank car, etc

-

3. 5083 aluminum plate for tank body of tank car is used for tank car, automobile, bus, ship, etc

-

4. 5083 die aluminum plate is used for die, ship plate, automobile and electronic products

-

5. 5083 aluminum sign blank

Other applications of 5083 alloy

Manufacturer's production strength

-

1. Processing capacity: according to your requirements, provide aluminum plate processing, fixed length leveling, aluminum plate embossing, laser cutting, NC cutting, sheet metal bending, anodizing, fluorocarbon spraying, sign rivet welding, film pasting, etc.

-

2. Processing quality: we have a strong production team and a variety of new production equipment to meet the quality requirements of processing parts in different industries. We use your drawings to select appropriate equipment for production.

-

3. Product quotation: the enterprise factory directly connects with you without any agent or agency link. It integrates the production of scattered orders offline to reduce the operation cost. You are welcome to consult and compare the quotation

Spot inventory, complete variety,Multiple quality inspection, reliable quality

5083 aluminum plate Corrosion Resistance

Excellent in a wide range of atmospheric environments, in food processing and architectural applications. The principal application for 5083 is marine environments. The magnesium content is more than 3½% Mg, so this alloy can be susceptible to stress corrosion cracking, which limits its application temperature to below 65°C and also limits the amount of cold work to ¼ Hard.

Special intergranular corrosion and exfoliation corrosion tests are carried out to certify 5083 for marine applications .

Alloy 5083 aluminum plate sheet is a non-heat-treatable 4½% magnesium, 0.15% chromium, 0.7% manganese alloy commonly available in flat rolled plate from a range of producing mills. Like all the 5000-series high magnesium alloys 5083 achieves a high strength by cold working,enabling a series of “H” tempers;

5083 aluminum alloy corrosion resistant

Heat Treatment

Alloy 5083 is not hardenable by heat treatment. It can be significantly hardened by cold work (eg by cold rolling) and various “H”tempers are produced – most commonly H32 (¼ Hard) or the similar strength marine tempers H116 and H321 – as well as the soft annealed Temper O condition.

The alloy spontaneously age-softens at room temperature immediately after cold work but will eventually reach a stable condition; all flat rolled mill products are supplied with stable properties. This is usually achieved by a stabilisation thermal treatment as the last operation which results in the H32 or H321 tempers. H112 temper is strain hardened as the final operation, again to quickly reach the required stable temper properties. To soften Alloy 5083 it can be annealed by heating to 345°C, hold until uniform temperature then cool; the rate of cooling is not important.

Welding

Excellent weldability by all standard electric and resistance methods; gas welding is not recommended. GMAW and GTAW are preferred and widely used to produce structural welds. When welding 5083 to itself or another alloy in the 5xxx series, the recommended filler metal is 5183. Other fillers are possible. Welding of strain hardened tempers will reduce strengths in the heat affected zones.

5083 aluminum plate supplier

Signi aluminum is a professional aluminum plate manufacturer, mainly engaged in aluminum plate, pattern aluminum plate, road sign, etc. Complete products, affordable prices, quality assurance, short delivery time, welcome to inquire. Or send your request to service@signialuminium.com

We will contact you as soon as we see the information.

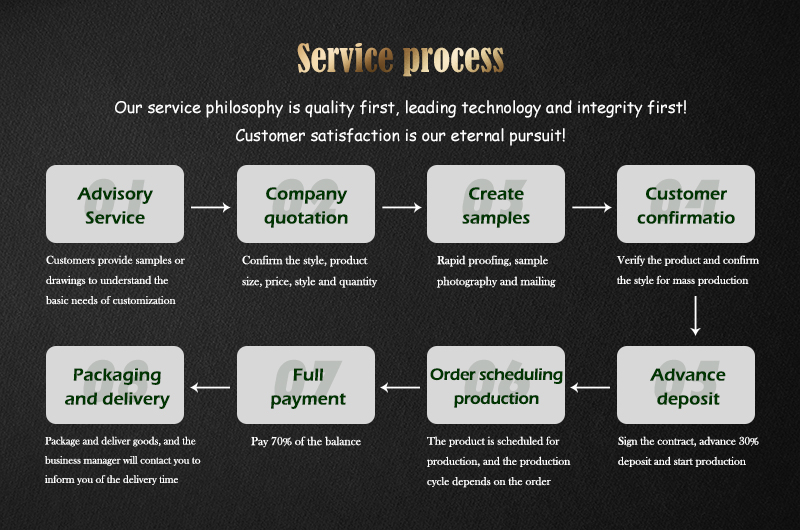

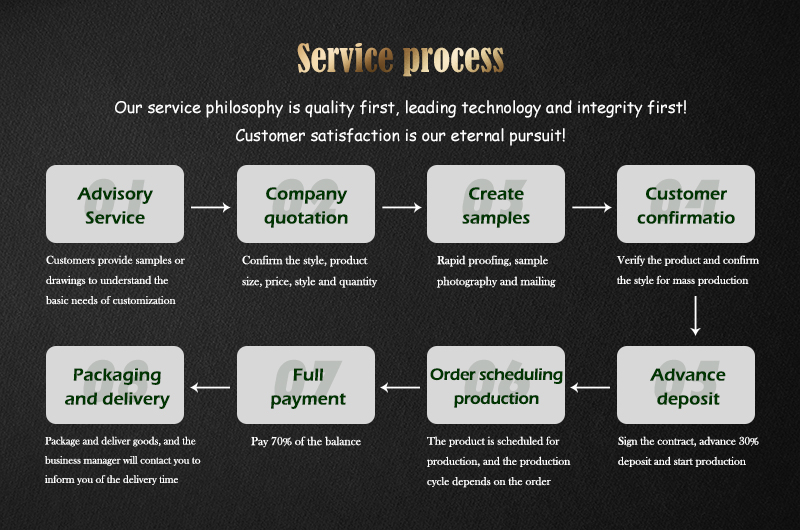

5083 service process of aluminum plate manufacturer

Machining

Machinability of 5083 aluminum plate sheet is poor due to its high strength.

Typical Applications

Applications:

LNG ship construction

Pressure vessels

Storage tanks

Welded structures (high strength)

Armor plate

Drilling rigs

Plate for ship building, unfired welded pressure vessels, rail and other vehicles, various structural applications that make use of the high strength.

Alloy: 5083

Temper: O, H111, H112, H116, H321,H12,H14, H16, H18, H32, H34, H36

Thickness: 0.2mm--200mm

With: 500mm--2800mm

Length: 1000mm--12000mm

Surface: Mill finish, Bright finish, paper interleaved, one side film, both sides film.

Chemical Properties

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Ni |

Zn |

Ti |

Ga |

V |

Others |

Aluminium

min. |

|

Each |

Total |

|

5083 |

0.4 |

0.4 |

0.1 |

0.4-1.0 |

4.0-4.9 |

0.05-0.25 |

- |

0.25 |

0.15 |

- |

- |

0.05 |

0.15 |

Remainder |