The construction industry is one of the three major markets for aluminum, and about 20% of the world's total aluminum production is used in the construction industry. The aluminum plate is an important part of the aluminum used in construction. Signi aluminum takes you to see the application of aluminum plate in the construction industry

The advantages of aluminum alloy in building construction

Compared with steel and other metals, glass, concrete and plastic materials, aluminum alloy has many advantages

-

Corrosion resistance

-

The surface is scratch resistant

-

Easy to clean

-

Multicolor

-

Low density and low weight

-

Easier extrusion molding

-

Low recyclable cost, green and environmental protection

-

Saving land and construction costs

What are the types of aluminum sheets for construction?

Due to different needs, different types of aluminum sheets are derived from aluminum sheets for construction:

Corrugated Aluminum Sheet

Definition: Its cross-section is wavy and dedicated to exterior wall decoration.

Features: It is a building material with the advantages of light weight, high strength, fire resistance, beautiful appearance, earthquake resistance, ventilation, waterproofing, heat preservation, sound insulation, convenient transportation and construction, etc.

Corrugated Aluminum Sheet

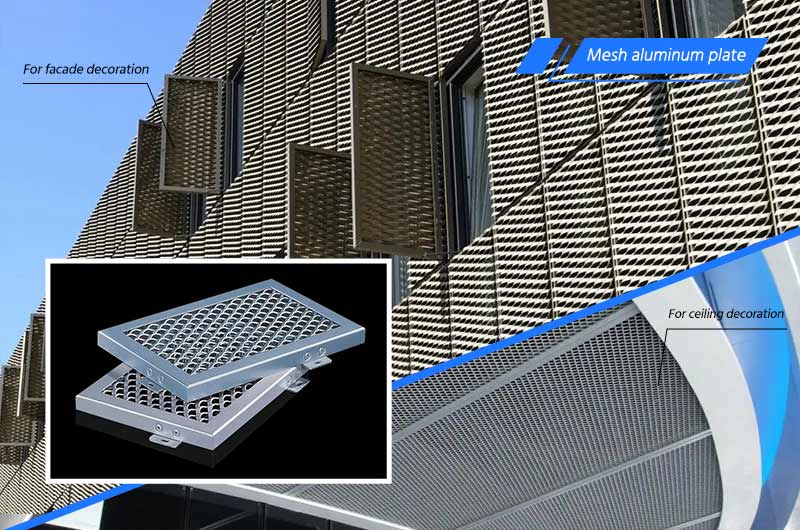

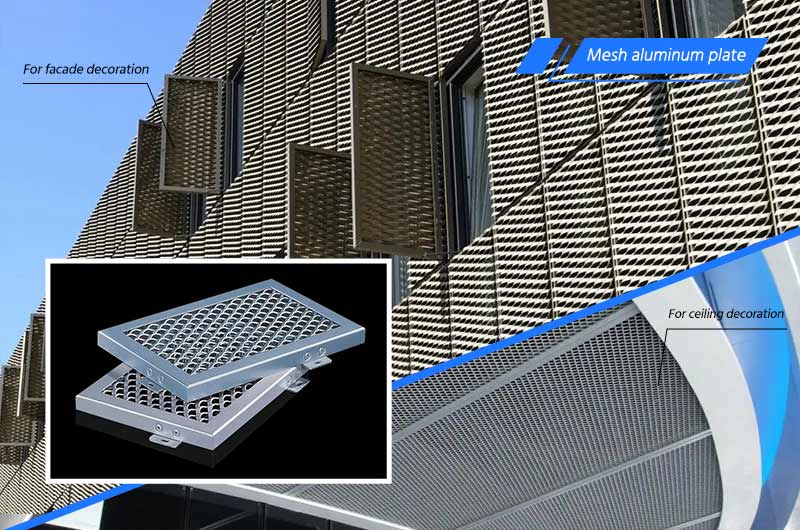

Aluminum mesh plate

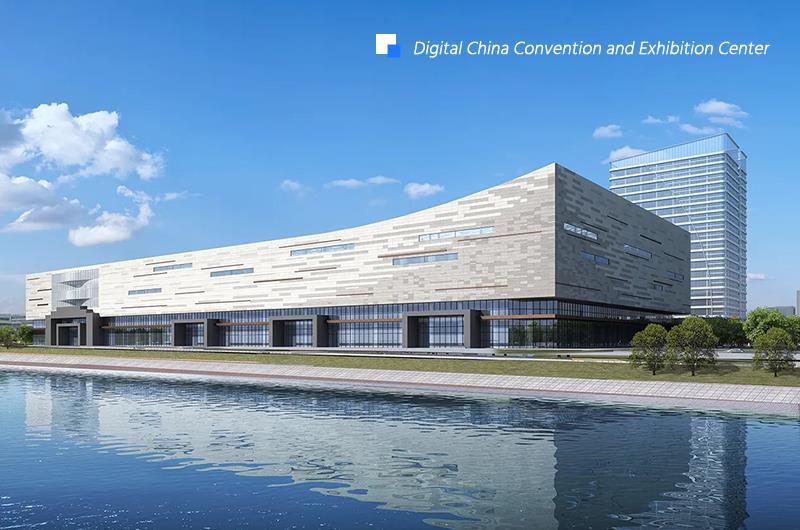

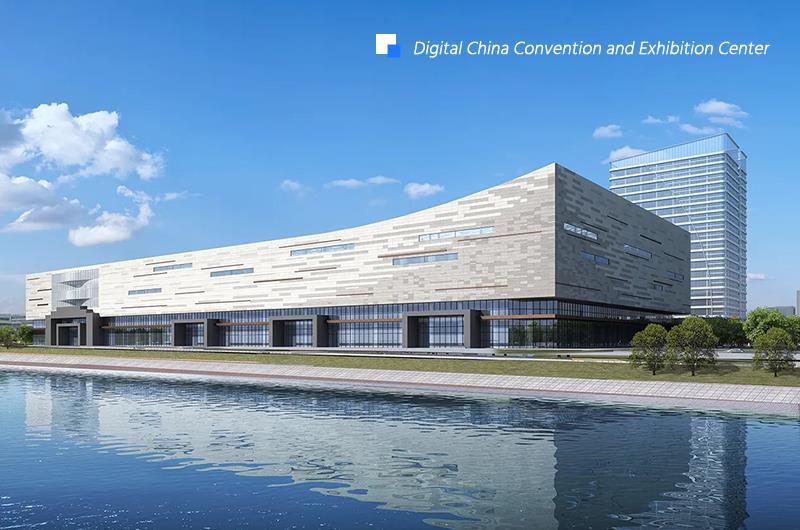

Definition: Mesh aluminum veneer is a high-quality aluminum alloy sheet as the base material, after bending and other techniques, the surface is sprayed with decorative paint. It is used for decoration of interior and exterior walls of buildings, lobby facades, etc.

Features: light weight, good rigidity, high strength, good weather resistance and corrosion resistance, good workmanship, uniform coating and various colors.

Aluminum Foam Plate

Definition: After adding additives to pure aluminum or aluminum alloy, foam aluminum plate is formed by foaming process.

Features: sound absorption, sound insulation, light weight, high specific stiffness, excellent electromagnetic shielding performance, non-burning and good heat resistance

Perforated aluminum sheet

Definition: A rectangular material with a rectangular cross-section and uniform thickness made of pure aluminum or aluminum alloy material by pressure processing.

Hole type: round hole, square hole, prismatic hole, triangular hole, pentagram hole, oblong hole, etc.

Features: good bending strength, good wind pressure resistance, light weight, high strength, corrosion resistance and other characteristics.

Which building components use aluminum panels

Aluminum plate for curtain wall

The aluminum panels used in construction include single-layer aluminum panels, composite aluminum panels and other materials. The aluminum plate curtain wall is mostly used for wall shielding and dark walls, and the aluminum plate curtain wall is made of single-layer aluminum plate.

Because it can get sprayed surfaces of various colors, it has good strength, low cost and long life. If it is not in direct contact with steel, the aluminum plate will not fall off and corrode for 50 years if it is hung on the wall.

Its common thickness is 1.5, 2.0, 2.5, 3.0MM, the model is 3003, and the state is H24. Among them, the 5005 curtain wall aluminum plate is more popular among the public.

Aluminum retaining wall fence

Wall panels are also called wall skirts and siding. The main application is the design of the background wall, TV wall, sofa wall, bedside background, etc.

All-aluminum siding has good constant temperature and noise reduction, which can not only effectively protect the building walls, but also have excellent decorative properties.

Partition wall aluminium plate

-

The biggest feature of the aluminum partition wall is the sound insulation effect, followed by the shortening of the decoration construction period of the aluminum alloy partition wall.

-

Mitigation of ambient air pollution

-

Convenience for intelligent electrical communication network wiring.

-

It is a great help for the freedom of interior designer space layout.

-

For office areas, VIP halls, corporate displays, and product exhibitions, the sound insulation and furniture compatibility is very good.

Aluminium roofing sheet

Roof slabs are slabs that can directly bear roof loads. Roof panels are located on the roof of the house.

Features of aluminium roofing sheet: light weight, high strength, corrosion resistance, prevention of light pollution, diverse surface treatments, beautiful appearance, good plasticity, easy processing, convenient installation, environmental protection, etc.

Aluminum Ceiling Sheet

The two areas of the kitchen and bathroom have large fumes, humidity, and many pipes on the roof. The aluminum ceiling sheet has the advantages of fireproof and moisture-proof, anti-corrosion and anti-electricity, sound absorption and sound insulation, and is the best choice for kitchen and bathroom ceilings.

Why choose Signi Aluminum as a supplier?

-

Over 12 years of experience in building, stocking and supplying architectural aluminum panels

-

Best prices for construction aluminium panels - available worldwide with shortest delivery times

-

Exporting architectural aluminum sheets to ASTM, EN standards is our specialty

-

We can handle the logistics for you - we can provide FOB, CIF delivery to any port

-

The documents we provide include – Certificate of Origin, Chamber of Commerce certified invoice and PL, Test certificate according to EN 10204 3.1, other test reports as our customers may request.

Appreciation of famous aluminum buildings