PS plate is also called pre-coated photosensitive plate. It refers to the aluminum plate for printing. It is a lithographic printing plate in which a photosensitive resin layer is pre-coated on the aluminum plate and the like by the manufacturer. The PS plate is composed of a photosensitive layer and an aluminum substrate or plate base that plays a supporting role. Due to the very high annual consumption of the PS plate, the number of aluminum plates required is also very high. The aluminum plate is not only its important support, but also plays an important role in the performance of the PS plate.

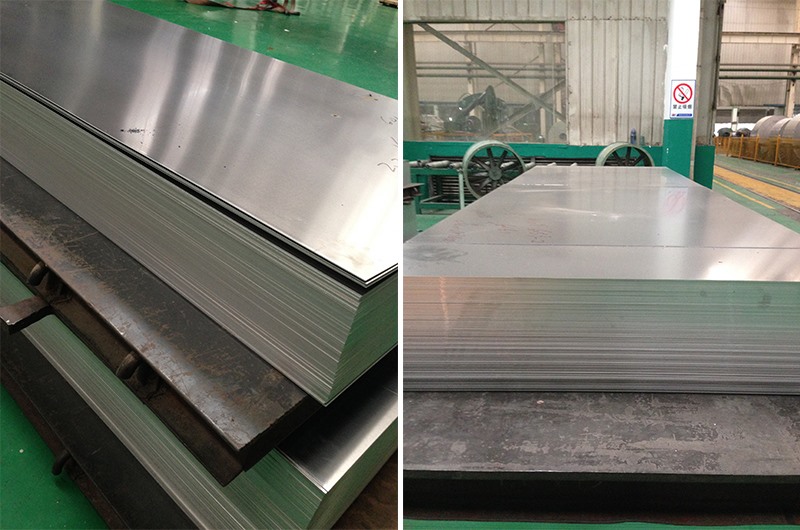

1050 aluminium PS plate

For the production of 1050 aluminium PS plates, it is required to have sufficient strength, good dimensional viscosity and flatness, and have a surface state and chemical composition suitable for de-molding. At present, most of the 1050 1070 aluminum alloy rolled PS plates with 0.2-0.28mm thickness are produced with a small amount of 3003 aluminum alloy. The most commonly used plate is the 1050 aluminum plate. In addition to being used for printing PS plates, the alloy is also widely used in offset printing plates such as positive PS plates, thermal CTP plates, photosensitive CTP plates, UV-CTP plates, etc. .

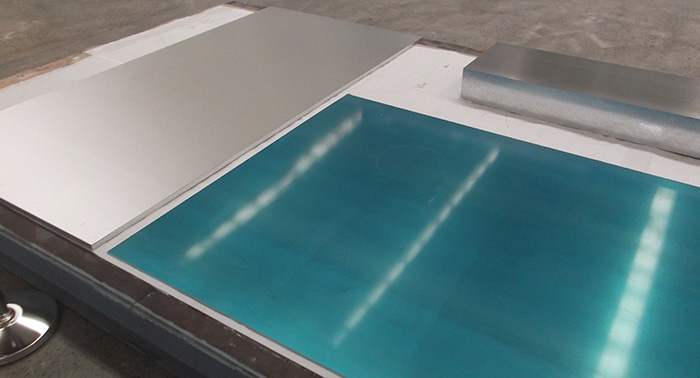

Because the 1050 PS plate base aluminum strip requires high surface quality and straightness, in order to obtain a high-quality PS plate base strip, a special straightening method must be adopted after cold rolling. In addition, the sand mesh value of the PS version is generally 0.60~0.80μm. To obtain finer mesh, the internal composition of the aluminum edition base is the key, that is, it is related to the content and composition of trace special metals contained in the aluminum alloy.