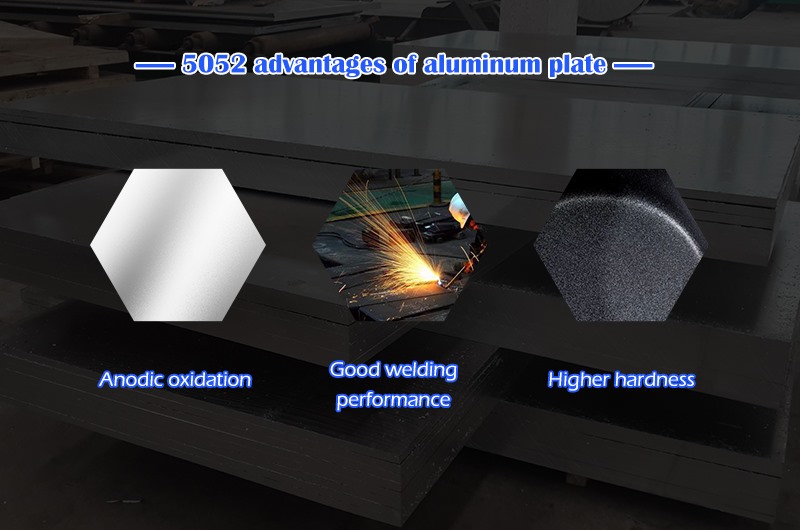

5052 Anodizing Oxidation Aluminium Alloy Plate

5052 Anodizing Aluminum Plate Features and Application

- 1. H32 temper tensile strength close to 5052, H36 temper close to 6063 T6, adopt 3C products to the lightweight demand.

- 2. After anodising oxidation, grain materials are close to 6 series materials, and the brightness is better, meet the requirement of high surface quality.

- 3. Belong to 5 series high strength Aluminium alloy, short production procedure and better stamping effect, meet the requirement of mobile、laptop’s surface.

Physical Characteristic

1. 5052 Anodizing Aluminum Plate Mechanical Properties

| Project | Tensile Strength | Yield Strength | Elongation | Strength | Bend Performance | Cup convex value |

|---|---|---|---|---|---|---|

| 5252 H32 | 235 | 180 | 12.4 | 73 | 0t | 6.4 |

| 5252 H36 | 250 | 215 | 7.0 | 82 | 90°/1t no crack | 5.6 |

| 6063 T6 | 250 | 220 | 13.2 | 83 | 90°/1t crack | 4.8 |

5052 Anodizing Aluminum Plate Electricity and Thermal Properties

| Project | Thermal Conductivity (20℃)/W˳(m˳k)-1 | Volume Coefficient (20℃)*10-6 K-1 | 20℃ electricity Conductivity (%IACS) |

|---|---|---|---|

| 5252 H32 | 138 | 69 | 35 |

| 5052 H32 | / | 69 | 35 |

5052 Anodizing Aluminum Plate Anodize Treatment

| Aluminium Alloy | Depth Indicator (L value) | Red Green Indicator (a value) | Yellow Blue Indicator (b value) |

|---|---|---|---|

| 5252 H32 | 90.8-90.9 | -1.3 ≈ -1.1 | 1.1-1.2 |

| 5052 H32 | 87.3-87.7 | -1.0 ≈ -1.2 | 1.1-1.4 |

5052 Anodizing Aluminum Plate Product Specification

| Thickness Range/mm | Thickness Bias/mm | Width Range/mm | Width Tolerance/mm |

|---|---|---|---|

| 0.2-3.0 | +-2% | 100-1600 | +-1 |