With the continued development of China's economy, the automotive industry's requirements for environmental protection and light weight are becoming higher. The car has become something that all families cannot do. The auto industry is showing signs of vigorous development. And weight reduction has become the most widely used lightweight material for bodywork.

In 6016 aluminum sheet, magnesium, chromium, silicon and other alloying elements can be used to obtain high strength aluminum alloy materials. The strength of ordinary car steel is about 240MPa, the high strength steel is 500-700MPa, and the strength of car aluminum alloy can reach 500MPa. Therefore, the specific strength / density of the aluminum alloy is high. Under the condition of equal strength planning, aluminum alloys are combined. Gold is lighter: 6016 aluminum plate can reduce the weight of the engine block and cylinder head by 30% -40%. The aluminum body is more than 40% lighter than the steel body. The weight of aluminum alloy wheels is reduced by approximately 50%.

6016 Aluminum Foil is a special automotive aluminum foil material, which has good forming ability and firing hardening performance. 6016 O-state flexible foil is suitable for various bending forming processes. 6016 aluminum alloy plates with different states and alloy properties have different uses in car manufacturing, such as car exterior panels, hoods, doors, boot covers, roof covers and other body covers.

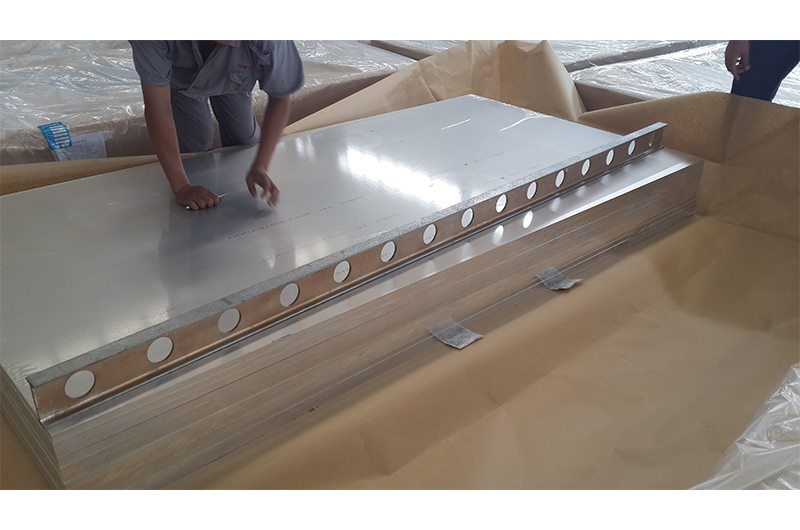

Henan Signi Aluminum Co., Ltd. supplies 6016 aluminum sheet, which can be used for all auto parts and bodywork. Hemming is an important process in the process of assembling and stamping the inner and outer panels of automobile covering parts. The flex limit is an important indicator to measure the performance of 6016 aluminum sheet hem.