The main alloying elements of 6061 aluminum plate are magnesium and silicon, which have medium strength, good corrosion resistance and good oxidation effect. 6061 aluminum plate is widely used after heat treatment. 6061 aluminum alloy thick plate is used in automatic mechanical parts, precision machining and various mold manufacturing.

6061 aluminum plate common state:

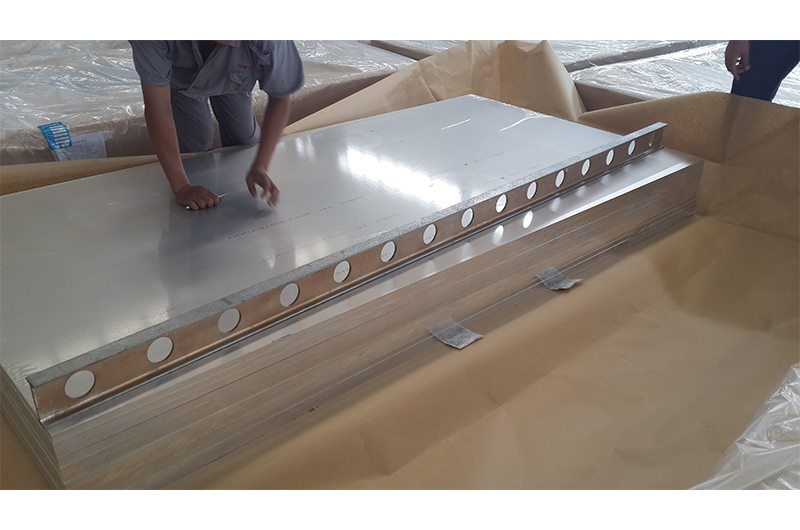

The T6 state is the most used of the 6061 aluminum alloy. The 6061 medium plate is quenched by medium-thick plate - medium plate slicing - stretching machine - aging treatment - sawing - polishing - packaging. The whole production cycle is about 10 days. After the solution heat treatment, it does not need to be cold-worked, and can be straightened and leveled without affecting the mechanical properties.

The F state is a free-processed state of 6061 aluminum alloy, which is suitable for special products for work hardening and heat treatment conditions during the molding process. F-state production cycle is very short: plate cutting - sawing - polishing (also can not be polished, according to customer requirements) - packaging, the entire process is arranged smoothly for 3 days to ship, F-state mechanical properties do not make specifications, customers can according to their own needs The F state is further subjected to heat treatment processing and used in a desired state. The corresponding price is also the cheapest.

The O state is a processed product in which the 6061 aluminum alloy is completely annealed to obtain the lowest strength. Applicable to the thin plate of 6061 aluminum alloy below 8.0, its production process: cold rolled finished product thickness - stretch bending cleaning - complete annealing - flying shearing (or bending and bending finished products) - packaging and storage, etc. Cycle is second only to T6 state