7050 T7451 aviation aluminum plate sheet is a high strength heat treatable alloy with high strength and resistance to spalling and stress corrosion cracking. Commonly used in aircraft structural parts for medium and heavy plate extrusions, free forgings and die forgings. The requirements for the manufacture of such parts are: resistance to flaking corrosion and stress corrosion cracking, fracture toughness and fatigue resistance.7050-T7451 aluminum plate has complete specifications and reliable quality. It is widely used in aviation, automobile, ship, electrical appliances, equipment and other fields.

7050 T7451 aviation aluminum plate

7050 aluminum plate is mainly used to manufacture aircraft structure and other high stress structural parts requiring high strength and corrosion resistance, such as aircraft upper and lower wing wall panels, stringers, etc. after solution treatment, it has good plasticity, good heat treatment strengthening effect, good strength below 150 degrees, and particularly good low-temperature strength.

7050 Alloy is used for aircraft lower wing panel

| Typical alloy | 7050 aluminum plate |

|---|---|

| Material status | F、O、T、H |

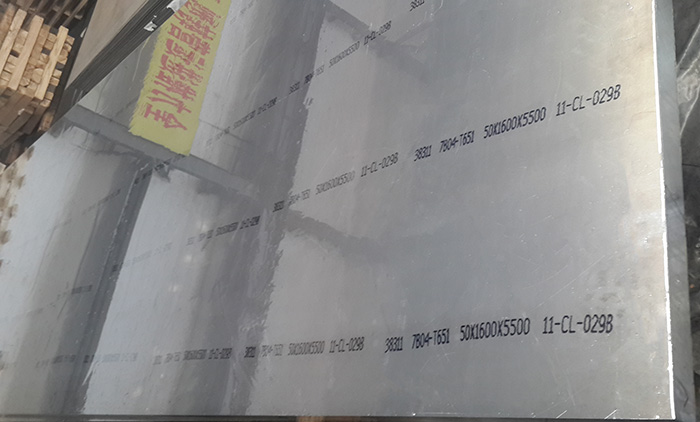

| 7050 status | 7050-T76 thin plate, thick plate, super thick plate 7050-T7451、7050-T7651 board 7050-T74、7050-T7452 die forging, forging 7050-T73511、7050-T74511、7050-T76511 extruded bar |

| thickness(mm) | 1.0-600 |

| width(mm) | |

| length(mm) |

7050-t7451 Mechanical properties

7050-t7451 Physical property

7050 t7451 high strength aluminum sheet

Mechanical behavior

State Tensile strength Yield strength Elongation Hardness (a) Shear strength Fatigue strength (b)

MPa ksi MPa ksi sample thickness

1.6mm (1/16in) HB MPa ksi MPa ksi

T73510 496 72 434 63 12 135 - - 71 10.4

T7451 524 76 469 68 11 135 303 44 71 10.4

T7651 552 80 490 71 11 135 324 47 71 10.4

Note: (a) Load 500kg diameter 10mm ball; (b) R.R.Moore type test, cycle 5*108 times full reverse stress.

Density: 2.83 g/cm3 (0.102 lb/in3) at 20 ° C (68 ° F).

Annealing temperature 415 ° C (775 ° F)

Solution temperature 475 ° C (890 ° F)

Aging temperature 120-175 ° C (250-350 ° F)

chemical composition

Aluminum (Al) balance

Chromium (Cr) ≤ 0.04

Zirconium (Zr) 0.08~0.15

Zinc (Zn) 5.7 ~ 6.7

Silicon (Si) ≤ 0.12

Iron (Fe) 0.000 ~ 0.150

Manganese (Mn) ≤ 0.10

Magnesium (Mg) 1.9 ~ 2.6

Titanium (Ti) ≤ 0.06

Copper (Cu) 2.0 to 2.6

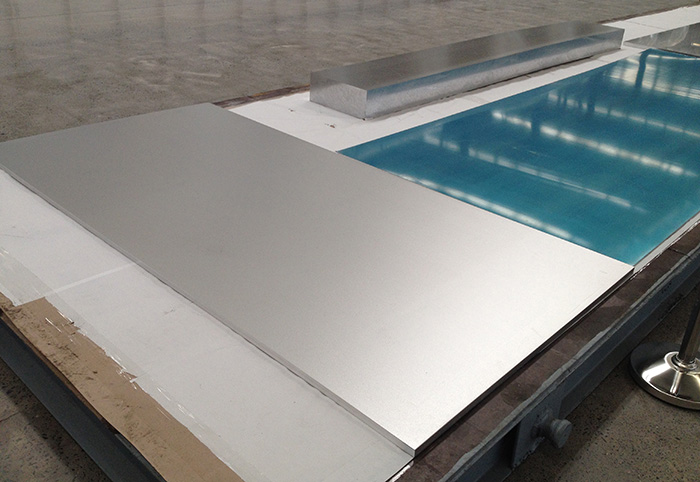

7050 aluminum sheet coated to prevent oxidation

There are many aluminum plate manufacturers in the market, but if you choose a good aluminum plate manufacturer, you can save a lot of worry. Signi 7050-T7451 aluminum plate manufacturer not only has guaranteed product quality, but also can design a set of reasonable schemes for customers to choose according to customers' needs, so that customers can not worry when purchasing, but also provide thoughtful after-sales service.