The 7175 alloy is a typical aerospace super-hard aluminum, AL-Zn-Mg-Cu alloy. It is now the main material for the key structures of aerospace vehicles. Only in composite materials can be mass-produced and the price is reduced to super-hard aluminum. When it comes to competitiveness, super-hard aluminum will withdraw from the historical stage and give way to composite materials.

The 7175 super hard aluminum alloy has a fairly large family. The commonly used alloys are 7075/7175/7475 alloys, of which the 7175 alloy is cleaner than the 7075 alloy, while the 7475 alloy is cleaner, ie their impurity content is lower than one, such as the 7475 alloy. The silicon content is only 25% of the 7075 alloy, which is 0.30% smaller than that of the 7075 alloy, so the 7475 alloy has higher toughness and better overall performance.

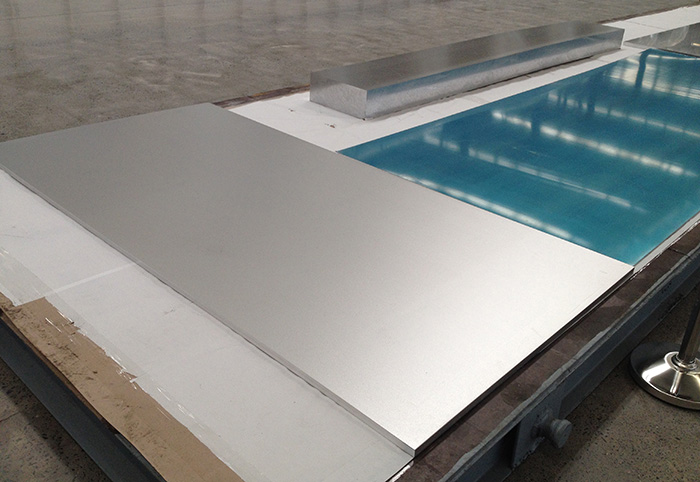

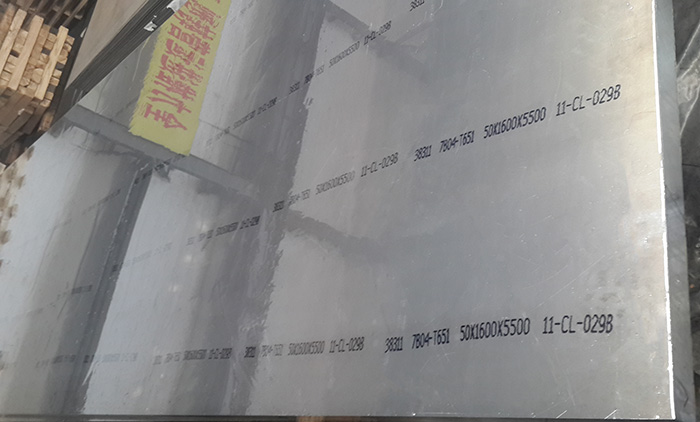

The 7175 super hard aluminum alloy is an aluminum-zinc-magnesium-copper heat treatable high-strength deformed aluminum alloy that can be used to process all semi-finished products for the manufacture of a wide variety of structural components, particularly aerospace structural components. Wide range of high-strength aluminum alloys, large to the front fuselage of the C919 large aircraft, passenger forged window frame forgings, medium fuselage bends and long rafts, keel beam webs, floor turning beams, mid-rear fuselage, passengers Observe the window frame forgings, the cargo door frame, the front of the head of the pressure box, the door frame, etc.; It has a variety of heat treatment conditions: T6, T73, T76, T77. T6 state material has the highest mechanical strength properties, but the fracture toughness is low, sensitive to stress corrosion, and its toughness decreases with temperature. Therefore, T6 state material is not suitable for manufacturing low temperature structural parts and workpieces; T73 material has the lowest strength However, it has a relatively high fracture toughness, good resistance to stress cracking and flaking corrosion resistance; T76 material has higher strength than T73 material and higher resistance to stress corrosion cracking than T6 material. The static strength properties of the 7175 super hard aluminum alloy are higher than those of the 2024 and 2124 alloys, and the fatigue properties are comparable. O-state and W-state materials have good room temperature forming properties.