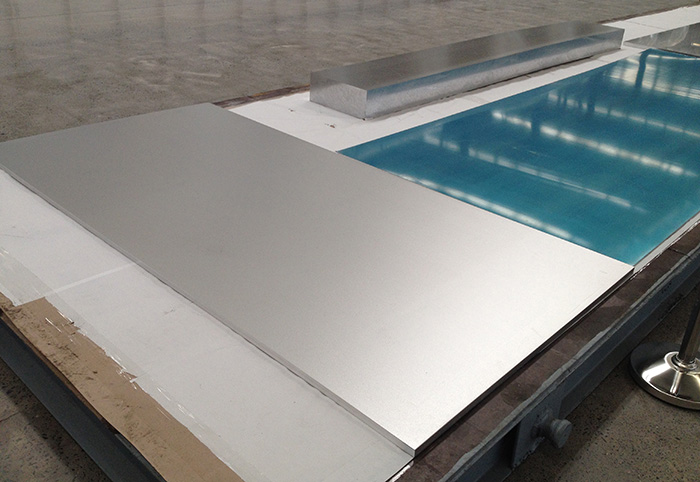

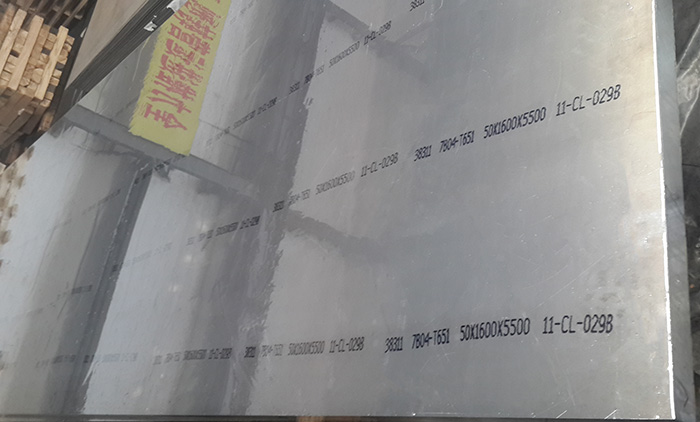

The 7A09 brushed aluminum plate is a manufacturing process in which the aluminum plate is repeatedly scraped out of the line with sandpaper. In the process of receiving pressure from the aluminum plate, the aluminum plate is forcibly passed through the mold under the action of external force, the metal cross-sectional area is compressed, and the technical processing method for obtaining the required cross-sectional shape and size is called an aluminum plate drawing process. A tool that changes the shape and size of an aluminum plate is called a wire drawing die.

Nowadays, more and more aluminum alloy products use a wire drawing process in the metal casing. Then. What are the benefits of the wire drawing process? Why is the wire drawing process so popular?

In fact, this wire drawing process can produce a film layer containing a specified metal component on the surface of the aluminum plate. Each of the fine silk marks can be clearly visible, resulting in a fine hairline luster in the metallic matte.

The aluminum plate treated by the wire drawing process can remove the surface pattern of the aluminum plate and play an aesthetic and anti-erosion effect, so that the product has both fashionable and technological elements and is more decorative.

Aluminum plate drawing generally has straight wire drawing, chaotic drawing, corrugated drawing and spinning drawing. The decorative effect of each pattern is also different.