Why is Automotive grade aluminum used in cars ?

The biggest purpose of using Automotive grade aluminum in the automobile industry is lightweight.

Automotive grade aluminum technology is one of the trends of the development of automobile technology nowadays, and the large-scale use of aluminum alloy and other materials is an important way to achieve the strength of vehicle body.

The United States, Japan and Germany are the countries that use the most aluminum alloys for automobiles, such as Volkswagen Audi A8 and A2 in Germany, and NXS in Japan. The amount of aluminum alloys for car bodies reaches 80%. In addition to the aluminum alloy used by Shanghai Santana, FAW Audi and Jetta (all imported production lines), there are more domestic cars with red flags, about 80-100kg.

Replacing traditional steel structure with aluminum alloy structure can reduce the weight of automobile by 30% ~ 40%, reduce the weight of engine by 30%, and reduce the weight of wheel by 50%. The use of aluminum alloy is one of the important ways to lighten the automobile, protect the environment, save energy, speed up and transport efficiently.

The main advantages of Automotive grade aluminum are light weight and good heat dissipation. It also has the advantages of corrosion resistance and beautiful surface.

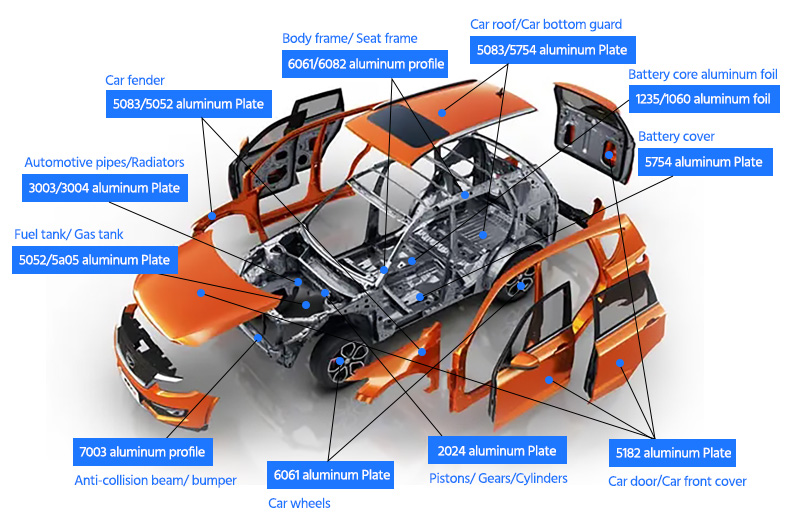

Application of automobile aluminum plate:

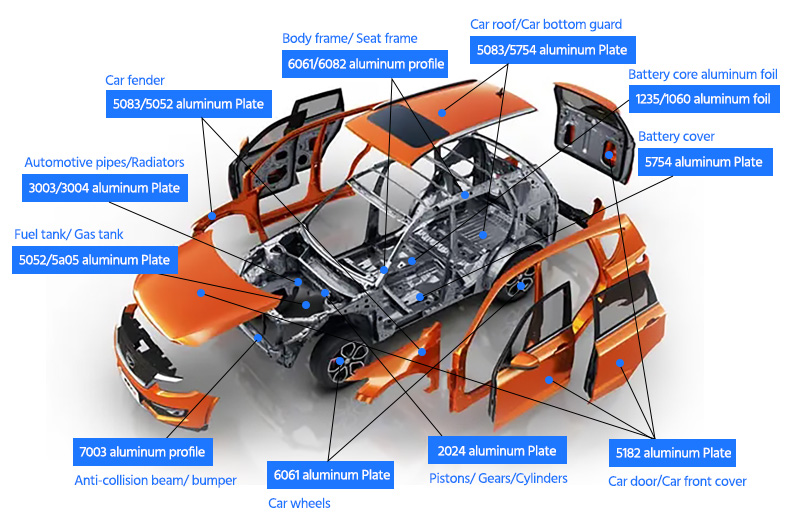

The deformed automobile aluminum plate is mainly used for manufacturing body panels such as doors and suitcases, bumpers, engine covers, spokes of wheels, wheel hub covers, wheel exterior trim covers, protective covers of brake assemblies, silencing covers, anti lock braking systems, heat exchangers, body frames, seats, chassis and other structural parts, as well as decorative parts such as instrument panels.

Aluminium sheet for car body

The application proportion of plates in cars is increasing. For example, 6000 Series (AI mg Si series) automotive grade aluminum plates that have been heat treated (such as T4, T6 and T8) can well meet the requirements of cars for shells and can be used as body frame materials.

The Aluminium sheet for car body metal parts of Audi A8 are made of 6000 Series (AI mg SI) automotive grade aluminum materials. In addition, 2000 series (AI Cu mg Series), 5000 Series (AI mg Series) and 7000 series (AI mg Zn Cu Series) automotive grade aluminum can also be applied to vehicle body materials.

Other aluminum alloy sheet for structural auto parts

Automotive grade aluminum is also widely used in other parts of automobiles, such as: General Motors of the United States uses

7021 Automotive Aluminum Plate to make bumper reinforcement brackets for smure cars, and Ford uses

7021 Automotive Aluminum Plate to make bumper reinforcement brackets for Lincoln Town cars. Automotive Aluminum alloy materials are also applied to automobile suspension parts, which effectively reduces the quality of corresponding parts and improves the smoothness and stability of automobile driving,

What alloy of Automotive Aluminium plate is used in automotive?

The main alloys for auto manufacturing include: 1100, 2024, 3003, 3004, 3105, 4032, 5005, 5052, 5083, 5182, 5251, 5754, 6016, 6061, 6181, 7003, and 7046. Automotive Aluminum is available in various formats and tempers which further benefit its popularity in the auto industry.

1100 aluminum alloy

The 1xxx series of aluminum is the most pure aluminum available. At 99% pure, 1100 aluminum sheet is extremely malleable. It also demonstrates excellent corrosion resistance. This was one of the first alloys used in vehicles and continues to be used today, primarily in heat insulators.

2024 aluminum alloy

The 2xxx series of aluminum is alloyed with copper. 2024 is often used in the manufacturing of pistons, break components, rotors, cylinders, wheels and gears as it shows high strength and excellent fatigue resistance.

3003, 3004, 3105 aluminum alloy

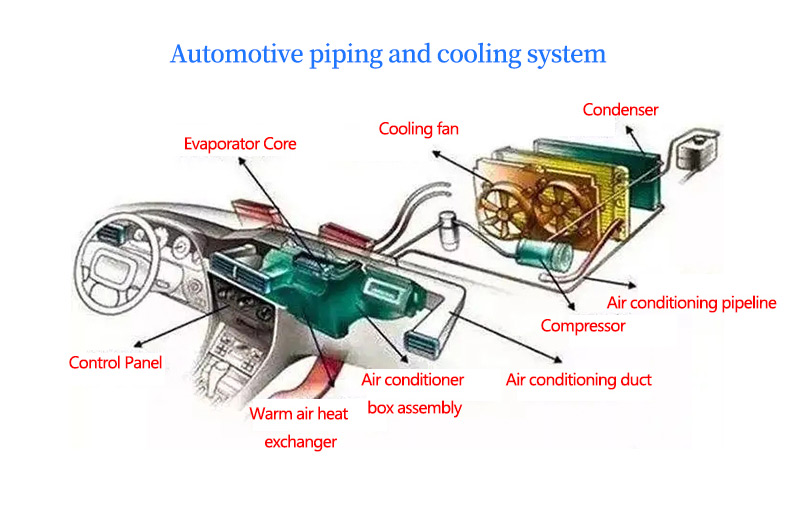

The 3xxx manganese series of aluminum has great formability. You’re most likely to see 3003, 3004 and 3105.

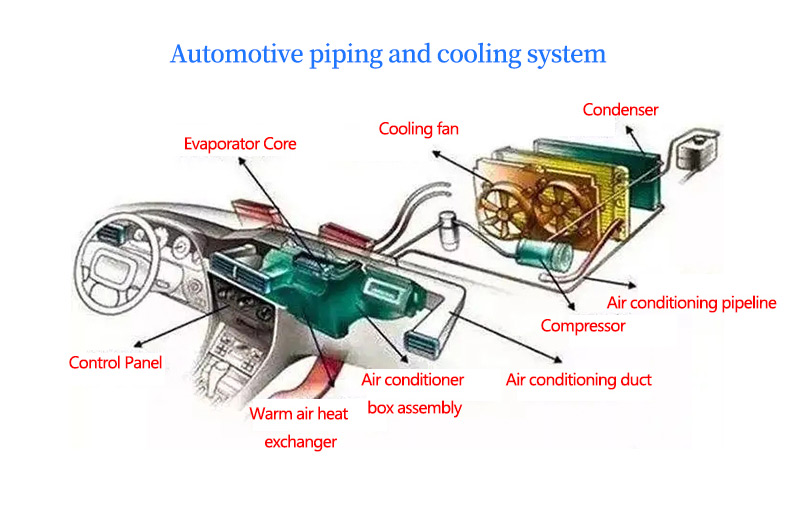

3003 shows high strength, good formability, workability, and drawing capabilities. It is often utilized for automotive piping, paneling, as well as power castings for hybrids and EV.

3004 shares many of the characteristics of 3003, and can be additionally purposed for cowl grille panels and radiators.

3105 has excellent corrosion resistance, formability, and welding characteristics. It shows up in auto body sheet, for use in fenders, doors, and floor paneling.

4032 aluminum alloy

The 4xxx series of aluminum is alloyed with silicon. 4032 will be used for pistons, compressor scrolls, and engine components as it demonstrates excellent weldability and abrasion resistance.

5005, 5052, 5083, 5182, 5251 aluminum alloy

5xxx series is one of the most popular for aluminum car bodies. Its main alloying element is magnesium, known to increase strength.

5005 shows up in body paneling, fuel tanks, steering plates, and piping.

5052 is considered one of the most serviceable alloys and appears in a multitude of auto components as a result. You’ll see it in fuel tanks, truck trailers, suspension plates, display paneling, bracketry, disk and drum breaks, and many other non-critical auto parts.

5083 is excellent for complex automotive components like engine bases and body paneling.

5182 shows up as a structural mainstay for car bodies. Everything from structural bracketry, to doors, hoods, and front wing end plates.

5251 can be seen in auto paneling.

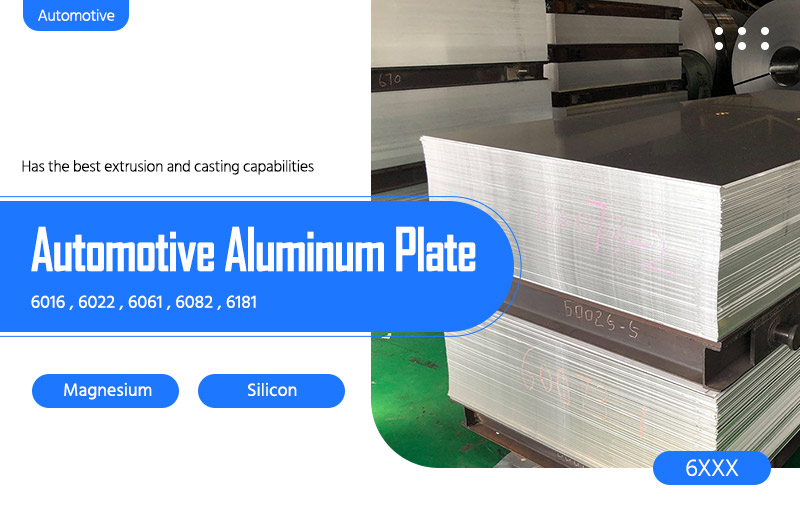

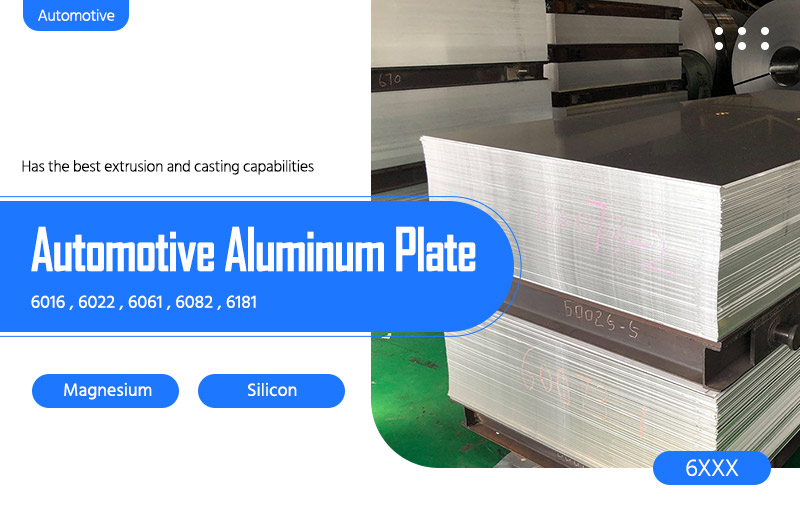

6016, 6022, 6061, 6082, 6181 aluminum alloy

The 6xxx aluminum series is alloyed with magnesium and silicon, they boast some of the best extrusion and casting capabilities, and demonstrate ideal surface finishing character.

6016 and 6022 are purposed in auto body covering, doors, trunks, roofs, fenders and outer plates where dent resistance is key.

6061 showcases outstanding surface finishing characteristics, corrosion resistance, and high strength. It shows up in cross members, brakes, wheels propeller shafts, truck and bus bodies, air bags, and receiver tanks.

6082 has some of the best impact resistance. Consequently, it’s used for load bearing framework.

6181 holds up as exterior body paneling.

7003, 7046 aluminum alloy

The 7xxx is the most powerful and highest strength alloy class, alloyed with zinc and magnesium.

7003 is an extrusion alloy used primarily for welded shapes in the making of impact beams, seat sliders, bumper reinforcement, motorbike frames, and rims.

7046 has hollow extrusion capabilities and good welding character. It shows up in similar applications to 7003.

Where are aluminium alloy used in car ? What are the advantages of lightweight?

Body lightweight

5182 automotive aluminum plate is specifically applied to car doors, front and rear covers.

Strip/sheet width: 1000-2300mm

Strip/sheet gauge: 0.15--600mm

5083 / 5052 automotive aluminum plate is specifically applied to automobile fender

Strip/sheet width: 1000 - 2300 mm

Strip/sheet gauge: 0.15-600mm

5083 / 5182 / 5005 automotive aluminum plate is specifically applied to car lifters.

5083 / 5005 automotive aluminum plate is specifically applied to automotive inspection fixture.

5083 / 5754 automotive aluminum plate is specifically applied to automobile roof and automobile bottom guard.

3003 / 5052 automotive aluminum plate is specifically applied to automobile fender .

Strip/sheet width: 20 - 2650mm

Strip/sheet gauge: 0.15-600mm

6061 automotive aluminum plate is specifically applied to the car seat frame.

Strip/sheet width: 100 - 2650mm

Strip/sheet gauge: 1-500mm

Chassis lightweight

6061 automotive aluminum plate is specifically applied to automobile hubs, truck hubs, and battery soleplates of new energy vehicles.

Strip/sheet width: 150 - 600 mm

Strip/sheet gauge: 0.30-600mm

Power system lightweight

5052 / 5083 / 3003 / 5A05 automotive aluminum plate is specifically applied to aluminum plates for fuel tank materials and heavy truck gas cylinders.

Strip/sheet width: 150 - 600 mm

Strip/sheet gauge: 0.30-600mm

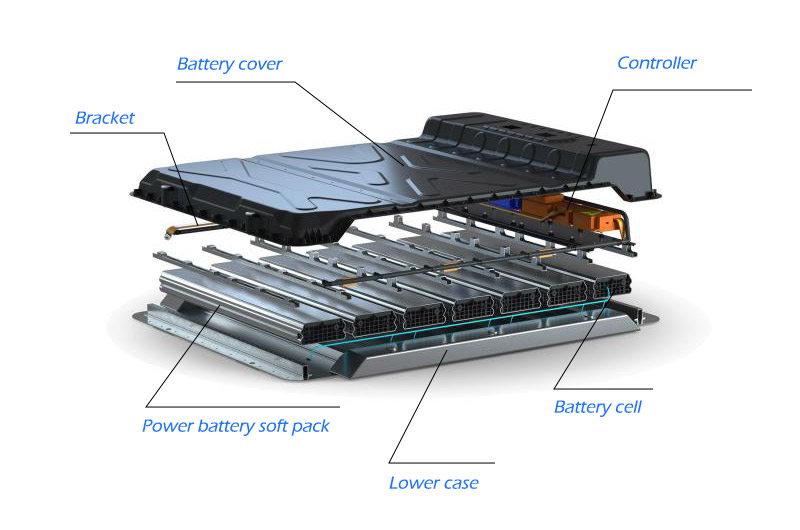

3003 / 6061 automotive aluminum plate is specifically applied to power battery shell materials.

Strip/sheet width:20 - 2650mm

Strip/sheet gauge: 0.20-4.5mm

5754 automotive aluminum plate is specifically applied to the battery cover plate

Strip/sheet width: 20 - 2650mm

Strip/sheet gauge: 0.15-600mm

1235 / 1060 / 1070 automotive aluminum foil is specifically applied to aluminum foil for battery cells

Strip/sheet width: 280 - 1700 mm

Strip/sheet gauge: 0.014/0.015/0.016mm

8021 / 8079 automotive aluminum foil is specifically applied to automotive power battery soft packs

Strip/sheet width: 280 - 1700 mm

Strip/sheet gauge: 0.014-0.20mm

At present, the all automotive aluminium plate body is limited to high-end cars and racing cars, but with the improvement of time and technology, the continuous decline of manufacturing costs and the increasingly strong voice of energy saving and emission reduction, more models of car body and parts will be made of aluminum.