Intruduction of the usage of oil tanker aluminum plate

5xxx series aluminum alloy plates are mainly used in cylinders, heads and compartments made of tank trucks after welding, wrapping or rolling and other processes. 5083, 5182, 5454, aluminum alloy wide sheets produced by Signi aluminum are suitable for tanker car bodies.

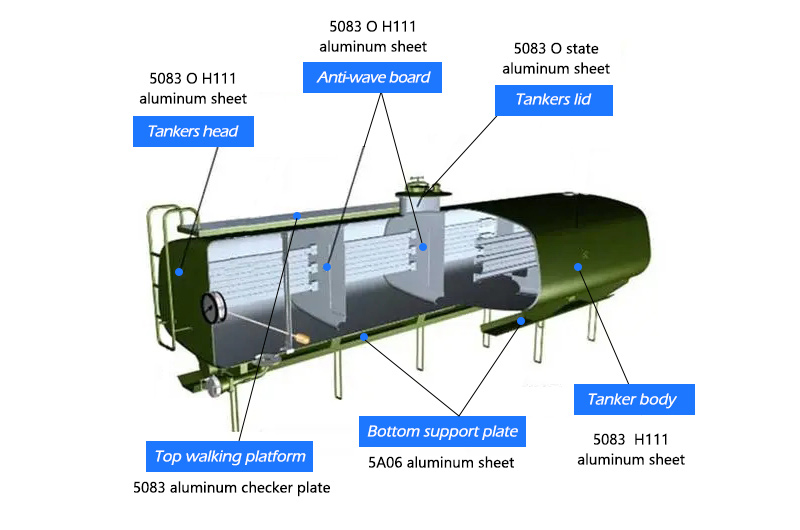

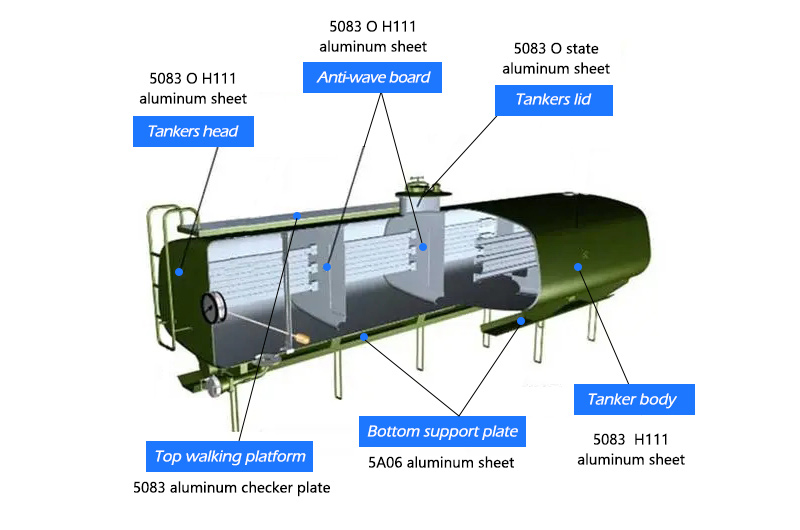

The aluminum plate of the tank body is welded by 5083 aluminum alloy plate. The plate thickness is 5~6mm.

Other components such as wash boards, partitions, and cans are also 5083 aluminum plates. The wall thickness of the can is equal to or greater than the wall thickness of the can. The thickness of the separator and wash board is 1mm thinner than the tank body.

The thickness of the left and right support plates at the bottom of the tank is 6-8mm, and the material is 5A06 aluminum plate. The top of the tank is provided with a guardrail and a walking platform. The walking platform is made of aluminum treads.

Aluminum plate alloys for fuel tanks include 5052, 3003, 5754 aluminum plates, etc. Aluminum has good oxidation resistance, corrosion resistance, and can well prevent chemical reactions with external substances, ensuring the service life of automobile fuel tanks. Therefore, it replaces the traditional Iron fuel tank and plastic fuel tank.

Intruduction of the oil aluminum plate

5083 aluminum sheet is a widely used in the manufacturing of fuel trucker. Its main element is magnesium, which has good welding performance, corrosion resistance and processing performance and medium strength.

5182 aluminum plate is used for the the latest high-magnesium alloy tanker which was born for the European road dangerous goods transportation agreement in recent years. Its tensile strength and elongation are relatively high. The excellent quality of 5182 alloy plate improves the safety of aluminum alloy tankers.

5454 aluminium plate is suitable for aluminum-magnesium alloy tankers used under high temperature conditions, with strong corrosion resistance.

Specifications of aluminum plate for tank car body

|

Alloy |

Thickness(mm) |

Width(mm) |

Length(mm) |

|

5083 |

2.0-8.0 |

1000-2650 |

2000-12600 |

|

5754 |

2.0-8.0 |

1000-2650 |

2000-12600 |

|

5454 |

2.0-8.0 |

1000-2650 |

2000-12600 |

|

5182 |

2.0-8.0 |

1000-2650 |

2000-12600 |

Chemical composition of aluminum plate for tank car body

|

ALLOY |

Si |

Fe |

Cu |

Mn |

Mg |

Ge |

Zn |

Ti |

other(%) |

Rminder |

|

5083 |

0.2 |

0.35 |

0.15 |

0.20-0.50 |

4.0-5.0 |

0.1 |

0.25 |

0.1 |

0.05 |

0.15 |

|

5754 |

0.4 |

0 |

0.1 |

0.5 |

2.6-3.6 |

0.3 |

0.2 |

0.15 |

0.05 |

0.15 |

|

5454 |

0.25 |

0.4 |

0.1 |

0.50-1.0 |

2.4-3.0 |

0.05-0.20 |

0.25 |

0.2 |

0.05 |

0.15 |

|

5182 |

0.2 |

0.35 |

0.15 |

0.20-0.50 |

4.0-5.0 |

0.1 |

0.25 |

0.1 |

0.05 |

0.15 |

Advantager of our company aluminum plate in usage of oil tanker

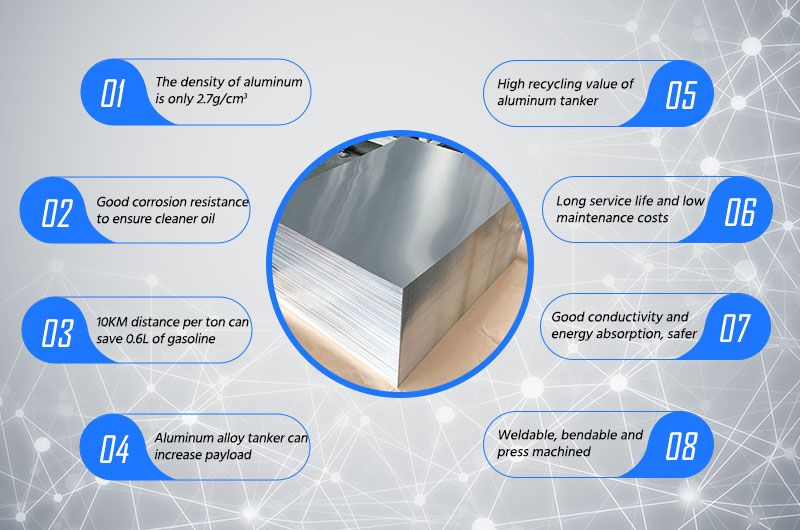

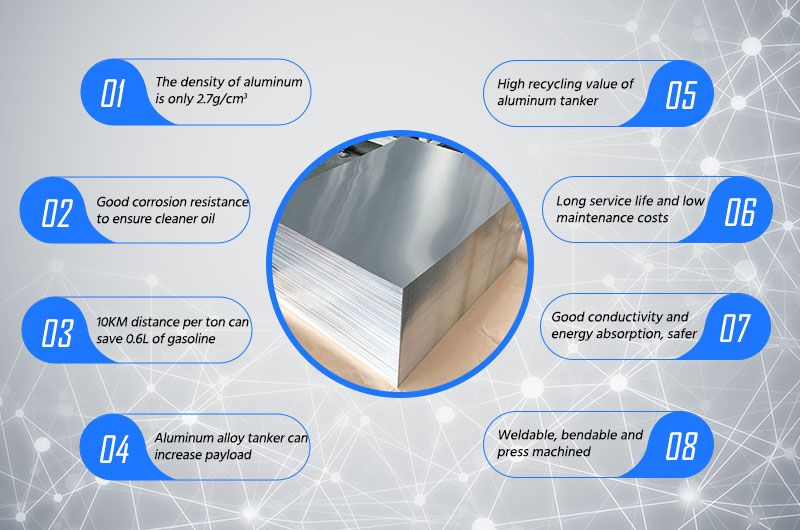

Lightweight

The density of aluminum is low, only 2.7g/cm3, and the same volume of aluminum alloy is almost only 1/3 of the weight of steel.

Strong corrosion resistance

Aluminum alloy has corrosion resistance that steel can't match. Tanks made of aluminum alloys can transport various liquids or liquefied gases without any protective layer inside.

Fuel economy

According to the relevant research report of the European Aluminum Association, every 1T of lights can save 0.6L of gasoline per 10KM.

Payload increase economy

If the aluminum alloy tank can be loaded with 5T cargo, calculated at 120,000 km/year, the transportation cost is 0.5 yuan/km.ton, and an additional 150,000 yuan/year can be added, and the economic benefits are very considerable.

High recycling value

Due to the high corrosion resistance of aluminum alloy, the aluminum alloy tank is not damaged much after the tanker is forcibly scrapped, and the recycling value of the tank is more than 85% of the original aluminum.

Long product life and low maintenance cost

The advantage of aluminum alloy is good corrosion resistance, which is more obvious in tanks that mainly transport effective and highly corrosive items.

Good electrical conductivity and energy absorption properties, safer

When the tanker collides, due to the good electrical conductivity of the aluminum alloy, there is little static electricity accumulated on the tank body, no sparks will be generated, and accidents such as explosions will be avoided.

Can be welded, bent and press processed without special processing technology

Welding methods such as MIG, TIG, resistance welding, and FSW can be used to weld aluminum alloys. At the same time, aluminum alloys can also be bent, stamped and deep drawn.