What is mirror finish aluminum sheet :

Mirror finish aluminum sheet refers to the aluminum plate with mirror effect on the surface of the plate through rolling, polishing and other methods. Even with the oxide film and coating generated by anodic oxidation, it can still maintain high finish and reflectivity, and maintain high scratch resistance, corrosion resistance, good strength and formability.

Why mirror polished aluminum plate sheet is used ?

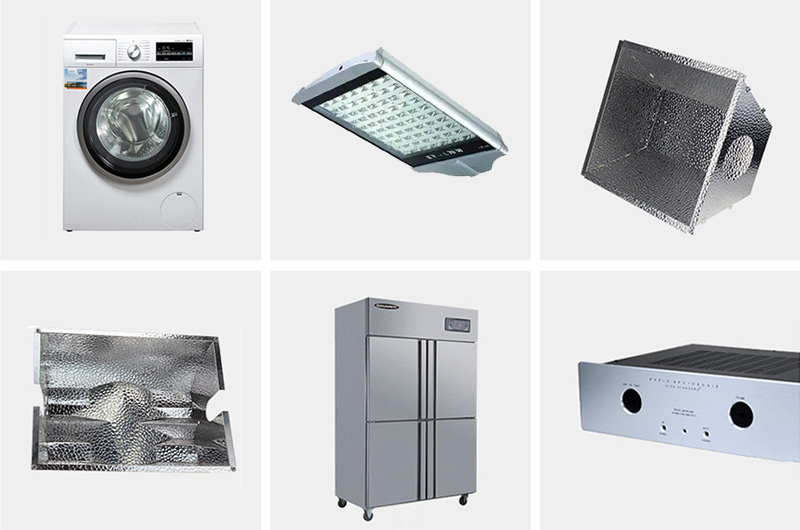

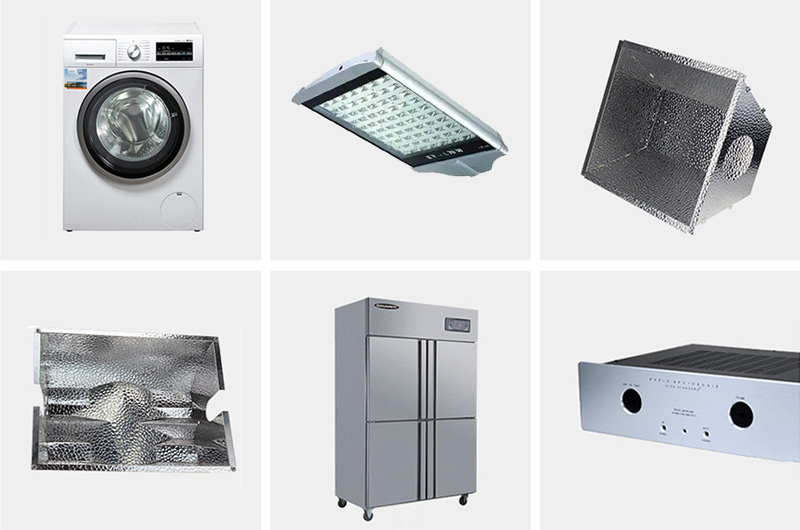

Mirror polished aluminum plate sheet is a newly developed aluminum plate and strip deep processing product in recent years. It can be used to process aluminum plate into mirror effect for decoration and reflection, and can replace mirror glass in decoration. Due to the fragility of mirror glass, it will cause many potential safety hazards. In recent years, it has been gradually replaced by mirror aluminum plate, and has been well applied in lighting equipment, high-end cosmetics, automobile or building interior and exterior walls and other fields. In recent years, with the rapid development of solar energy equipment and high-power LED lighting, the demand for reflective materials also shows a trend of rapid growth. As a new type of reflective materials, mirror aluminium is also being concerned by all parties, becoming a major innovation field in aluminum application.

Advantages of Signi aluminum mirror aluminum plates:

-

1. The surface is smooth and easy to clean: the mirror aluminum surface is smooth, even if there is dust, as long as you use a simple cleaning cloth, you can achieve ideal results. The product color is mostly silver white, which can highlight the characteristics of clean and tidy.

-

2. Glossy and beautiful: specular aluminum has many colors, good lighting effect and strong reflective ability. It is often used in building materials and automobile decoration to highlight the shape and overall structure, increase beauty and publicize individuality.

-

3. Light material, energy conservation and environmental protection: light material, reducing more energy consumption. For example, car hubs are more specular aluminum, which not only have beautiful luster, but also are not easy to oxidize and have a longer service life.

-

4. High reflectivity, fingerprint resistance, scratch resistance, oil resistance, no dents and scratches on the surface, and the stain is good for decoration.

-

5. Good impact resistance, light weight and easy maintenance.

-

6. High strength, high corrosion resistance, excellent weather resistance and sound insulation.

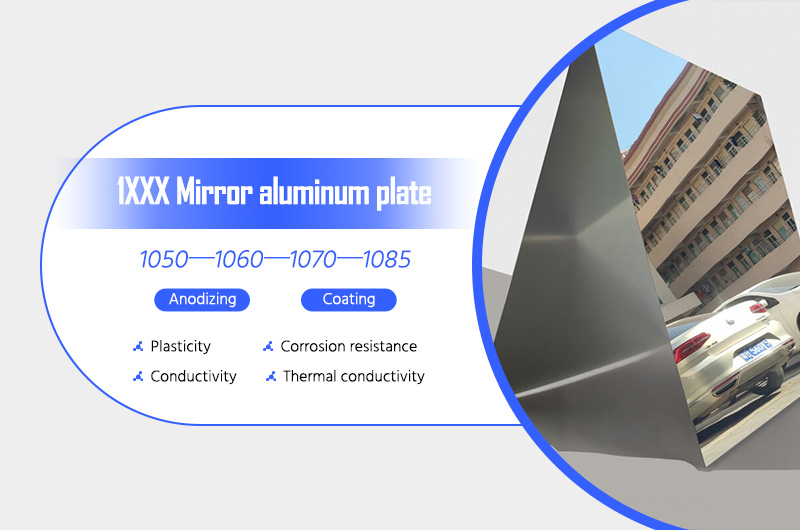

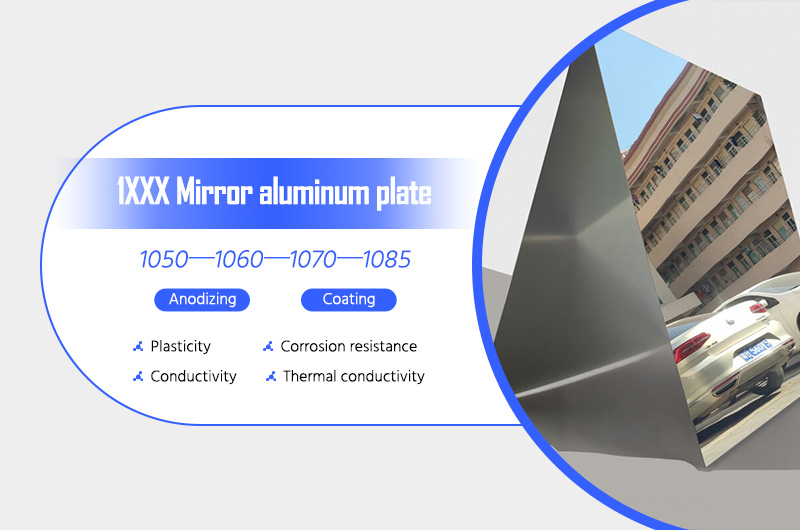

What are the main alloys and specifications of mirror aluminum sheet metal?

The main products of mirror aluminum sheet metal are 1xxx, 3xxx and 5xxx series aluminum alloy plates, and the representative alloy is 1050 1060 1070 3003 3105 5052 5005.

1050 1060 1070 mirror aluminum sheet metal belongs to pure aluminum, the most commonly used series. The production process is relatively simple, the technology is relatively mature, and the price has great advantages over other high-end alloy aluminum plates. It has good elongation and tensile strength, and can fully meet the conventional processing requirements (stamping, stretching) with high formability. It is industrial pure aluminum, with high plasticity, corrosion resistance, conductivity and thermal conductivity, but low strength. Heat treatment cannot strengthen the machinability. They have a certain corrosion resistance, but not as good as 3003 3105 5052 5005 mirror aluminum plate. If you want to have good corrosion resistance, the surface can be anodized aluminum mirror sheet , coated and other special treatment steps.

3003 3105 mirror aluminum sheet metal contains trace manganese element and has good corrosion resistance, so its rust resistance has been greatly improved, and it is a series with good rust prevention function. It is commonly used in humid environments such as air conditioners, refrigerators and car bottoms, and the price is higher than 1000 series. It is a commonly used alloy series.

However, 5052 and 5005 mirror aluminum sheet metal are superior to all other alloys. They contain another corrosion-resistant metal magnesium, which has high corrosion resistance and is characterized by low density, high tensile strength and high elongation. This series of alloy aluminum plates used as mirror surfaces can meet relatively high application requirements under the promotion of materials and related characteristics.

The reflectance of the mirror aluminum plate can reach 86%-95%

|

Product |

Reflective Rate |

Typical Alloy |

Typical Temper |

|

Mirror Aluminum |

86%-95% |

1050 1060 1070 3003 3105 5052 5005 |

O--H24 |

|

The Specification of reflective mirror sheet metal |

|

Thickness (mm) |

Width (mm) |

Length (mm) |

ID (mm) |

|

0.1 - 4.0 |

40- 1600 |

1000 - 6000 |

205,405,505 |

Different process applications of aluminum mirror plate sheet:

The aluminum mirror plate sheet is widely used. The aluminum mirror plate sheet processed by oxidation, polishing and other processes has the advantage of high reflectivity. It is mainly used in the fields of lighting reflector plate and lamp decoration, solar heat collection reflective material, electronic product shell and so on,

In addition, rolled aluminum mirror plate sheet is mainly used in interior architectural decoration, exterior wall decoration, household appliance panel, electronic product shell, furniture and kitchen, interior and exterior decoration of cars, signs, logos, bags, jewelry boxes and other fields.

What are the applications of anodized aluminum mirror sheet?

-

1:Mirror polished anodized aluminum sheet will be used on car signs, road signs and cosmetic boxes. Although these products are partially made of mirror aluminum, they play a crucial role in improving the product grade.

-

2: Secondly, the mirror polished anodized aluminum sheet is often used in the shell of electronic products, such as laptops, vertical air conditioners, furniture panels and other electronic products.

-

3: Nowadays, many LED lighting materials have also started to use specular anodized aluminum mirror sheet. With its ultra-high reflectivity, the light has been completely reflected, making the same LED bulb show high brightness under the effect of different reflectors. Therefore, LED lamps made of specular aluminum oxide have been widely used.

-

4: Anodized aluminum mirror sheet is widely used in the fields of lighting reflector and lamp decoration, solar heat collection reflective materials, household appliance panels, electronic product shells, furniture and kitchen, interior and exterior decoration of cars, signs, signs, bags, jewelry boxes, etc. It is also used in the interior architectural decoration and exterior wall decoration of high-end buildings. When the mirror aluminum plate is used indoors, it can fully demonstrate its unique charm. It can enhance the sense of space and create a sense of space extension

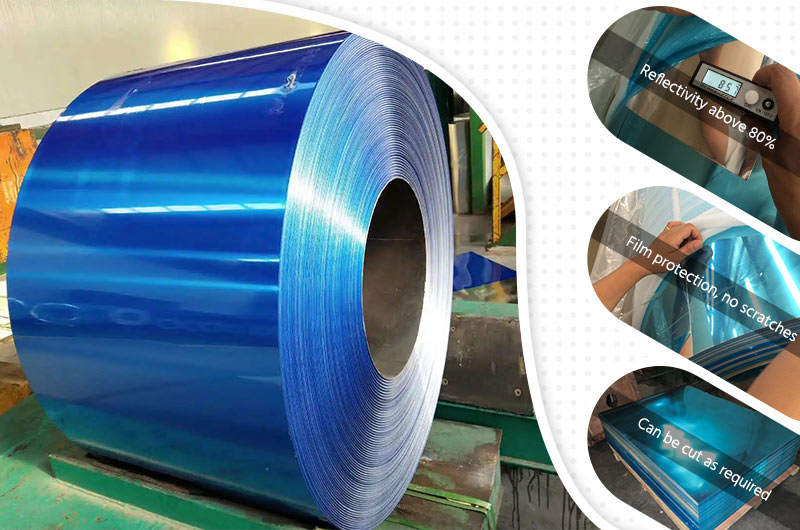

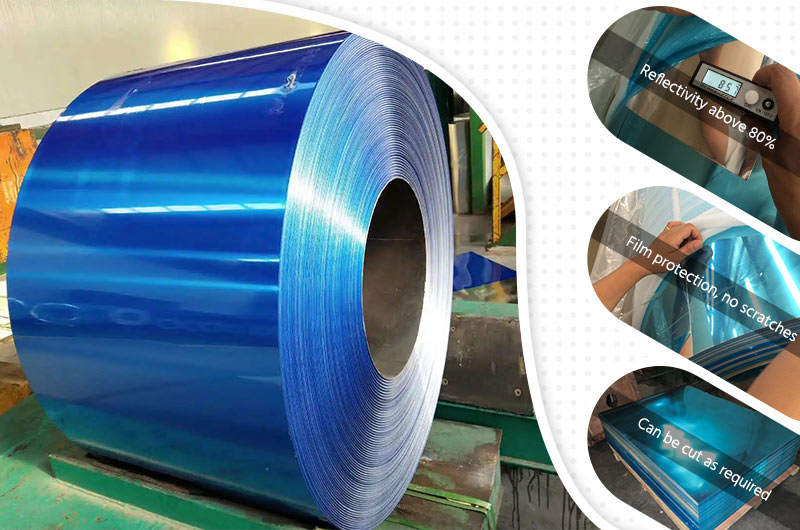

Why choose our mirror finish aluminum sheet ?

Signi Aluminum Co., Ltd provides high-quality mirror finish aluminum sheet products with a reflectivity of more than 80%, which can provide surface film with stable reflectivity. Specializing in the production of series of products such as Series 1 mirror finish aluminum sheet (1060, 1100, 1050, 1085), Series 3 mirror finish aluminum sheet (3003), Series 5 mirror finish aluminum sheet (5005,5052), etc. The surface of mirror finish aluminum sheet and mirror aluminum coil are pasted with protective film, which can ensure that the surface of the plate is smooth and clean without scratches, oil stains, stable reflective rate, and consistent reflective effect. It can be cut flat, in strips, and cut into various long and wide plates and strips.

The mirror aluminum plate and mirror aluminum coil of our company are made of high-quality aluminum plate and base material. The aluminum alloy mirror plate has strict quality control from raw materials to finished products, which can ensure the consistency of reflectivity of each batch of finished mirror aluminum plate. The stability of reflectivity of different batches of mirror aluminum plate. Signi Aluminum's mirror aluminium sheets is widely used by customers, replacing expensive imported products. At present, mirror aluminum plates (aluminum coils) with a thickness of 0.1-4.0mm can be provided, and the width is within 1600mm. Various sizes can be processed according to user requirements.