5083 h111 aluminum plate is a product with medium strength, corrosion resistance and good weldability. It is widely used in all fields from thin plate to thick plate.

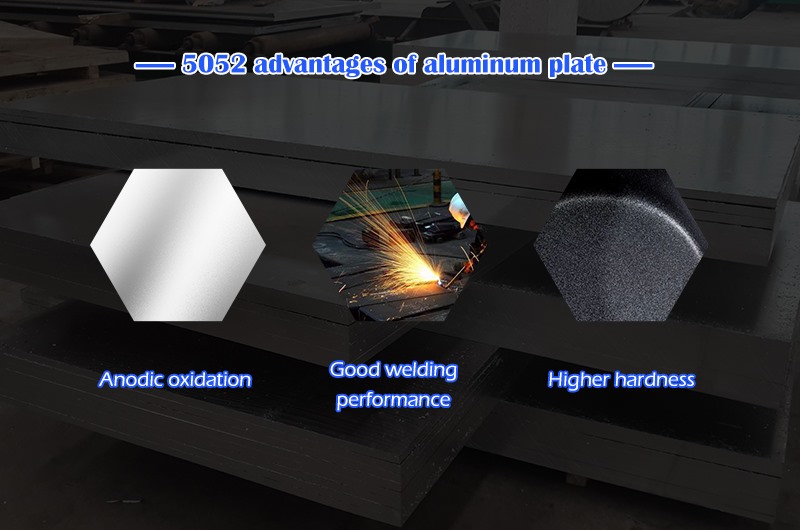

5083 h111 aluminum plate performance advantages:

- 1. High strength and good fatigue performance

- 2. Good corrosion resistance to marine atmosphere

- 3. Good weldability

5083 h111 aluminum plate is widely used in marine ships, automobile, aircraft welding parts, subway and light rail, pressure vessels resistant to strict fire prevention (such as liquid tank cars, refrigerated vehicles, refrigerated containers), refrigeration devices, drilling equipment, transportation equipment, missile parts, armor, etc

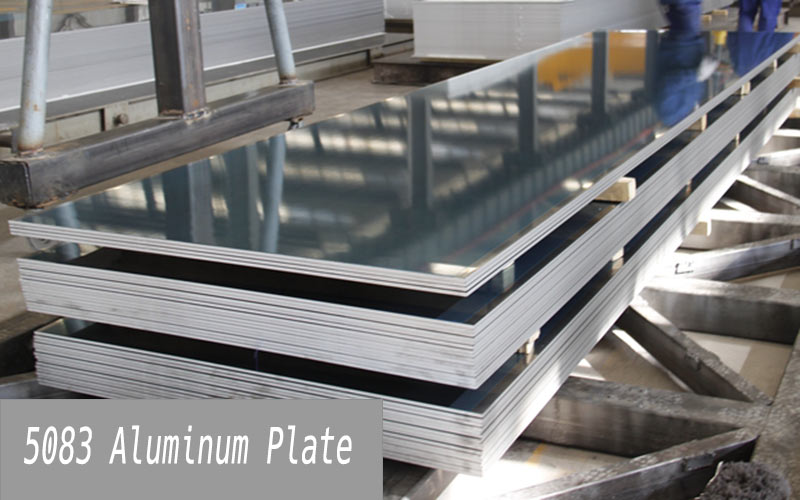

5083 H111 aluminum plate

Application of 5083 aluminum plate

5083 aluminum plate can be used for low temperature storage tank and large spherical tank for LNG transportation

The materials of large spherical tanks used for LNG transportation and transportation, low-temperature storage tanks, and LNG transported by ships at a temperature of minus 162 degrees Celsius, are considered to be a kind of clean energy. The world's largest aluminum plate is widely used in LNG storage tanks. These materials must be resistant to embrittlement at low temperatures, light weight, corrosion resistance and can be used to ensure safety during marine transportation.

5083 aluminum plate is a typical antirust aluminum plate and a commonly used marine aluminum plate. It is widely used in the field of shipbuilding due to its good performance

5083 H111 aluminum plate mechanical properties and tensile strength

| Aluminum alloy grade and status | tensile strength (250 ℃ MPa) | yield strength (250 ℃ MPa) | hardness 500kg force 10mm ball | elongation 1.6mm (1 / 16in) thickness |

|---|---|---|---|---|

| 5083 h111 | 275-350 | 210 | 65 | 16 |

5083 h111 vs h112

H111 is the attached standard of 5083 aluminum plate. For the attached standard of aluminum alloy, it is generally only the classification standard of different hardness after different heat treatment, which has little relationship with the main model.

5083 the difference between h111 and h112 is only the requirements of physical and mechanical properties, which depends on the required physical properties

H112 is applicable to products with certain characteristics obtained during thermal processing, which have mechanical property requirements.

5083 aluminum plate

Significance of 5083-h111 aluminum plate label

Subdivision of H state

H followed by an Arabic numeral

H1: only indicates the work hardening state, which is applicable to the products that obtain the specified strength without heat treatment after work hardening;

H2: work hardening and incomplete annealing state. It is applicable to products whose work hardening degree exceeds the specified requirements but whose strength is reduced to the specified requirements after incomplete annealing. For alloys softened and aged at room temperature, the final minimum tensile strength in H2 state is the same as that in H3 state. For other alloys, the final minimum tensile strength in H2 state is the same as that in H1 state, But the elongation is slightly higher.

H3: work hardening and stabilization state. It is applicable to products with stable mechanical properties after work hardening through low-temperature heat treatment or due to the thermal effect in the process of hot working. Stabilization usually can? Improve ductility. This code is only applicable to alloys gradually aged and softened at room temperature.

HX1 (x for 1, 2, 3) followed by an Arabic numeralYes! I'm interested

H1, H2 and H3 status codes are followed by an Arabic numeral to indicate the degree of work hardening. The number 8 represents the final tensile strength obtained by about 75% cold deformation (processing temperature not exceeding 50 ℃) after complete annealing. The states of O and 8 are represented by numbers 1-7 respectively. Wherein, when the final tensile strength is the intermediate value of O state and hx8 state, it is represented by the number 4 (hx4); When the final tensile strength is the intermediate value of O state and hx4 state, it is represented by the number 2 (hx2); When the final tensile strength is the intermediate value of hx4 state and hx8 state, it is represented by the number 6 (hx6). When the minimum tensile strength exceeds at least 10 MPa in the hx8 state, it is represented by the number 9 (hx9). When the number followed by HX code is odd, it indicates that its strength is the arithmetic mean of two adjacent even states.

When some metals cannot reach the minimum tensile strength of hx8 state by cold deformation (complete annealing and 75% cold deformation), the hx6 state can be determined by about 55% cold deformation or the hx4 state can be determined by about 35% cold deformation.

Hxx code followed by Arabic numerals

When there is a difference but close to the control degree or mechanical properties (or both) of hxx state, or there is a significant impact on the determination of other characteristics, the third Arabic numeral shall be used.

5083 h111 aluminum plate manufacturer

Signi aluminum is a large modern aluminum processing enterprise integrating scientific research, processing and manufacturing. The company can produce 1-8 series aluminum plate, strip and foil products with complete specifications and huge production capacity to meet your personalized processing needs.

5083 h111 aluminum plate manufacturer